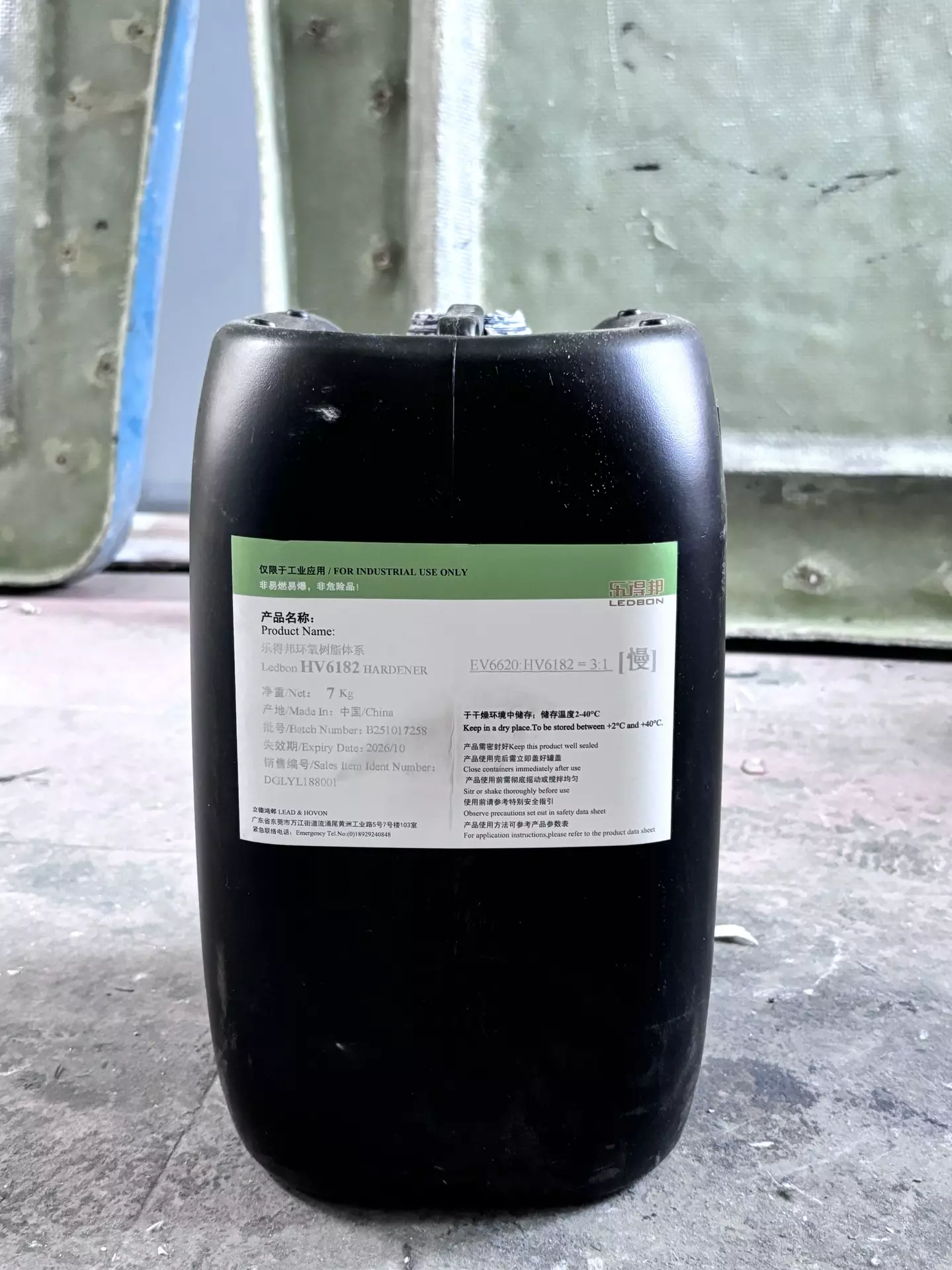

A curing agent is an essential additive that reacts with resin to transform it from a liquid into a solid state. In fields such as composites, coatings, and adhesives, curing agents promote resin cross-linking, significantly enhancing material strength, hardness, chemical resistance, and stability. Different resin systems require matching types of curing agents—for example, amine curing agents are commonly used for epoxy systems, while MEKP curing agents are typically used for unsaturated polyester resin and gelcoat. Choosing the right curing agent helps optimize curing speed, product performance, and final molding quality, making it a key factor in ensuring overall material reliability.

Company profile

Dongguan Jinhao Composite Materials Co., Ltd. specializes in the research, development, and production of carbon fiber products. With over two decades of industry experience and technological expertise, we consistently uphold the core principles of “producing premium products” and “pursuing customer satisfaction.”

Q1:What are your advantages?

A: We have strong suppliers who can provide professional services and competitive pricing.

Q2: Are you a factory or a trading company? What is your minimum order quantity?

A:Yes, we are a trading company. We are authorized direct sales agents for multiple brands and maintain some inventory. You may order as few as one piece for testing purposes.

Q3: How does your factory control quality?

A:All raw materials we use are environmentally friendly;2. Skilled workers handle every detail throughout the production and packaging processes;3. The quality control department closely monitors quality at every step.

Q4: Can I get a sample order?

A:Yes, we welcome sample orders for testing and quality inspection. Mixed samples are acceptable.

Q5: What is your delivery timeframe?

A:For products already in stock, it typically takes 1-2 business days. If we need to manufacture the product, it usually takes 5-7 business days.